B.15:45 Presents….

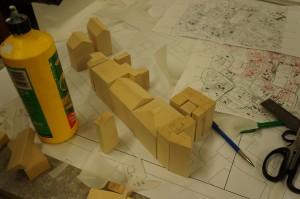

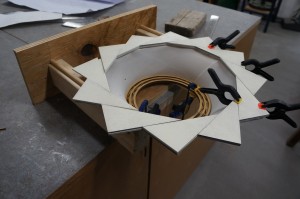

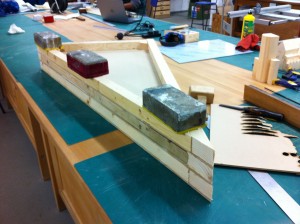

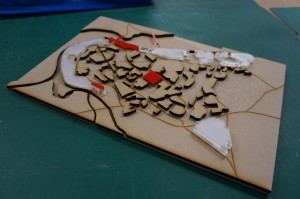

As part of our continued look at the role of Modelmaking in Architecture we are very pleased to announce our upcoming symposium event: Modelmaking in the Digital Age

The day will comprise of a series of talks and discussions around the subject of modelmaking in architecture, in particular the impact the introduction of digital tools has had on the approach to making and learning with models.

Registration for the symposium has now closed.

Confirmed Speakers for the event are:

Ken Grix, Architect and Modelmaker at Feilden Clegg Bradley Studios, Bath. Since 1999 Ken has been both the inspiration behind and creator of Feilden Clegg Bradley Studios’ concept models, design process models and presentation models. He became a Partner of the company in 2012, and the following year he achieved the great honour of winning the Lend Lease/AJ Grand Award for Architecture at the Royal Academy Summer Exhibition 2013 for his concrete concept models of the Festival Wing, Southbank.

Dr. Milena Stavric, studied Architecture at the University of Belgrade where she also received her PhD. Since 2004 she has worked at the Graz University of Technology, Austria. Author of Architectural Scale Models in the Digital Age: Design, Representation and Manufacture.

James Smith, Director and Head of Architectural Modelmaking at Amalgam Models, Bristol. James joined Amalgam in 2000 having gathered model making experience across the UK for several years, followed by 3 years based in Barcelona where he managed many high profile architectural projects. James became a Director at Amalgam in 2008.

Professor Nick Dunn, Professor of Urban Design at Lancaster Institute for the Contemporary Arts.Previously studied and taught at the Manchester School of Architecture, Author of the international best selling book, Architectural Modelmaking.

Gregor Anderson, Associate Partner at Foster + Partners and manager of the in-house Rapid Prototyping Facility. Gregor studied at the Royal College Of Art where he focused his research on all forms of digital manufacturing. On graduating, he was a key member in the development of Rapidform, the RCA’s in house additive manufacturing unit. In 2008 he moved to UCL to set up and run The Digital Manufacturing Centre in the Bartlett School of Architecture, before joining Foster + Partners in 2011.

Ed Bartlett, Associate and Modelshop CAD Support Manager at Foster + Partners. Ed joined the practice in 2008 after graduating from the Arts University Bournemouth, where he studied Modelmaking for Design and Media, specialising in computer-aided design. He now heads up a team of CAD specialists within the practice, working on a wide variety of projects around the world.

The event will be chaired by our own Dr Raymond Lucas. Dr Lucas has recently been appointed as Head of Architecture in Humanities at the University of Manchester and as such will have a close relationship with our workshop activities in future. His involvement teaching at MSA and research with the Manchester Architectural Research Centre (MARC) however has been ongoing for the last 4 years so Ray is well versed in the active role our cause plays for our students.

The event will be chaired by our own Dr Raymond Lucas. Dr Lucas has recently been appointed as Head of Architecture in Humanities at the University of Manchester and as such will have a close relationship with our workshop activities in future. His involvement teaching at MSA and research with the Manchester Architectural Research Centre (MARC) however has been ongoing for the last 4 years so Ray is well versed in the active role our cause plays for our students.

The event will be held on March 9th in the Cordingley Lecture Theatre here at the University of Manchester’s Humanities Bridgeford Street Building. Presentations will begin at 09.30am and will continue throughout the day with Q & A sessions and general discussions around the subject concluding no later than 16.00.

Further updates to the event will be posted here leading up to the event.

Tickets are no longer Available

Registration for the symposium is now closed.

For those who have registered We’ll see you on Monday!