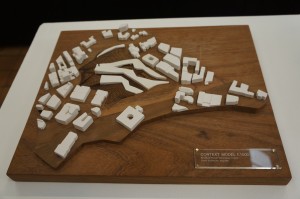

This 3rd Year contour model of a site in Stockport has been made to demonstrate the effects of pollution in the area. Smoke, trapped in the lower box section of the model will escape through holes on the base of the site representing pollution from the area. The river area will eventually be flooded and show and overspill to the surrounding urban area.

Models of this kind are described as being ‘Predictive models’ in that they are attempting to show how a change may occur over time. The process of ‘flooding’ on this model will likely result in its destruction so it’s life will be short.

The group used laser cut MDF to build up the site contours and band saw cut MDF for the site roadway. The buildings were made from Jelutong wood blocks and the base box from band saw cut acrylic with acrylic square section.

The group used laser cut MDF to build up the site contours and band saw cut MDF for the site roadway. The buildings were made from Jelutong wood blocks and the base box from band saw cut acrylic with acrylic square section.