Back in June there was much to be celebrated at the end of year show where many MSA students revealed their hard work to eager practice and public visitors. Part of the popular launch is the prize giving ceremony where students are selected for their prowess in specific areas of study. Drawing, Team-work, Innovation, Sketchbook, Academic and Visual achievement awards have been permanent fixtures at the school for many years. A more recent addition to this list is our own: The B.15 Modelmaking awards sponsored by Mecanoo.

For the past three years Netherlands based architects Mecanoo have generously supported our desire to celebrate the use of models within architectural design. The awards consider not just a single piece of work but each individuals attitude and approach to using physical models as a vehicle to advance the understanding of their design to both themselves and to others.

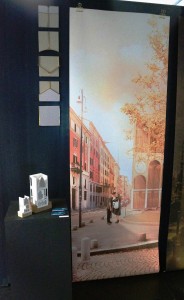

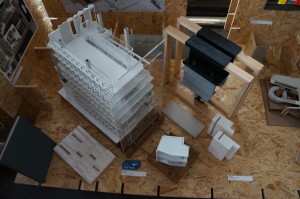

This has helped to stimulate an improved output in terms of typology and quality of the models produced across all years of study. This year highlighted that with the number of long-listed projects proving difficult to cut down. Seeing these projects develop over the academic year put us as technicians in a good position to see not only the physical changes in terms of the work but in each individuals attitudes to the idea of making in design and how its correct use can serve to inform key design decisions along the way.

This has helped to stimulate an improved output in terms of typology and quality of the models produced across all years of study. This year highlighted that with the number of long-listed projects proving difficult to cut down. Seeing these projects develop over the academic year put us as technicians in a good position to see not only the physical changes in terms of the work but in each individuals attitudes to the idea of making in design and how its correct use can serve to inform key design decisions along the way.

I decided to write this article to highlight a particular case in which a student initially struggled to grasp the idea of experimentation before settling on the most appropriate way forward with their work. The student won this years’ MArch first prize for his use of modelmaking. A prize which was well deserved and from our perspective a pleasure to award given the steep learning curve and effective turnaround that was made over the last two years of study.

James Donegan was one of the lucky few who managed to get selected to take part in the Material Application workshop that took place at the start of 2016. The main aims for this workshop were to encourage the use of testing in order for each student to better understand the processes they were looking at. Put simply, the high value was placed in seeing the mistakes made and not just in the analysis of a finished piece. James aimed to cast a staircase detail in plaster. I asked James to recount the experience:

“I spent too much time working on the computer and setting up cut files without really doing any research into the casting process and consequently, I ran into many hurdles and had to abandon the process all together. Although the project ultimately failed, the experience taught me the value of testing and sampling before any commitment.”

Despite having initial struggles to get his models to flow smoothly within his project it was clear from the technicians perspective that something was shifting in James’ approach.

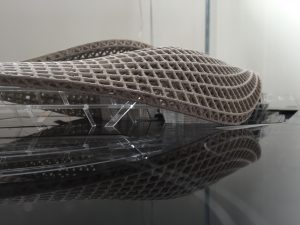

“I started to realise the process between translating a digital model into a physical one isn’t always easy, especially if you’re trying out something new. Even before I have a clear concept for a model, I would get into the workshop as early possible and start testing ideas which would feed back to inform my designs as well as the making process.”

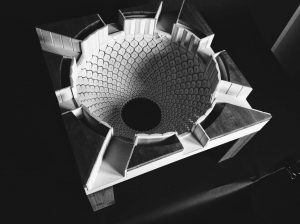

James’ outputs clearly grew and the content became much more varied and refined through constant testing. This was a notable change from his initial approaches which were driven entirely by computer manipulation.

So what tips would James offer to anyone wanting to make or improve the use of models within their design work?

“Always consult the technicians before starting on a process you’re not familiar with. It will save you a lot of time. If you can, get the basic modelmaking done at home – it’ll mean you can take full advantage of the facilities during the B.15 opening hours. Try to limit dependency on the popular machines like the laser cutter – a lot of the work people use it for can be done by hand and it usually looks better. Experiment and don’t let failure discourage you – its progress.”

James is now working locally at Tim Groom Architects. We wish him the best of luck for his future career.

Thanks to James Donegan for sharing this thoughts and recollections.

Scott