During a recent trip to Vienna I was lucky to catch the last day of an exhibition of the works of Gaudi at the Architekturzentrum Wien. The exhibition consisted of examples of furniture design alongside descriptions, slide shows of the major works and of course models.

During a recent trip to Vienna I was lucky to catch the last day of an exhibition of the works of Gaudi at the Architekturzentrum Wien. The exhibition consisted of examples of furniture design alongside descriptions, slide shows of the major works and of course models.

Of particular interest to our cause were the plaster models showing details and sections through parts of his buildings. The quality of these pieces was stunning and the photographs I was able to take really don’t do them justice.

Of particular interest to our cause were the plaster models showing details and sections through parts of his buildings. The quality of these pieces was stunning and the photographs I was able to take really don’t do them justice.

We can take from them is inspiration and a demonstration of the sort of insights models of this type can give us into the form and construction of a building. From my best insights a would say that models have been cast in sections and fitted together afterwards due to the fragility and complex shape of certain details. This method of Modelmaking requires the main focus on planning with a conscious thought for the casting process at all times. Martial tolerance and shrinkage is a key factor in designing parts to a particular size for assembly after casting.

We can take from them is inspiration and a demonstration of the sort of insights models of this type can give us into the form and construction of a building. From my best insights a would say that models have been cast in sections and fitted together afterwards due to the fragility and complex shape of certain details. This method of Modelmaking requires the main focus on planning with a conscious thought for the casting process at all times. Martial tolerance and shrinkage is a key factor in designing parts to a particular size for assembly after casting.  This facade section model of ‘La Pedrera’ in Barcelona shows the layers of supporting structure and outer form beautifully. In addition to the physical properties of the building demonstrated through the design, the shadows cast through window openings clear and defined giving accurate projections of how the interior space may change throughout the day.

This facade section model of ‘La Pedrera’ in Barcelona shows the layers of supporting structure and outer form beautifully. In addition to the physical properties of the building demonstrated through the design, the shadows cast through window openings clear and defined giving accurate projections of how the interior space may change throughout the day.

Part of the exhibition text explained the importance of models to any project Gaudi embarked on:

Part of the exhibition text explained the importance of models to any project Gaudi embarked on:

‘Gaudi put models before plans. For this reason he set up a workshop next to each of his buildings, where he studied and analysed, from as empirical and a craftsman’s point of view, the forms and structures that he later applied to his projects. This is what he called his “experimental method”, a method that is still in use in the Sagrada Familia Workshop although these days this process has been enhanced with the most advanced technological instruments.’ (Daniel Giralt-Miracle, Curator of the Exhibition)

Due to our restricted casting capability in B.15 we will be focusing on the accurate production of the ‘master models’ in a manner suited for molding and casting at the Chatham casting facility. As with all projects, consult myself or Jim as early as possible to achieve the most effective results in your time frame. If the project is too difficult at a later stage a high quality finish will be harder to achieve so don’t hesitate to start on receiving your brief.

Due to our restricted casting capability in B.15 we will be focusing on the accurate production of the ‘master models’ in a manner suited for molding and casting at the Chatham casting facility. As with all projects, consult myself or Jim as early as possible to achieve the most effective results in your time frame. If the project is too difficult at a later stage a high quality finish will be harder to achieve so don’t hesitate to start on receiving your brief. Also on display was this model 3D powder printed model of the entire Sagrada Familia (above). Producing a model of such complexity as a plaster cast would be achievable but in this case the powder printed method was chosen. Most likely due to the sophistication of each ‘spire’ component and it’s relationship to the next. Certainly for the conservation of time and as a retrospective piece this is very appropriate.Â

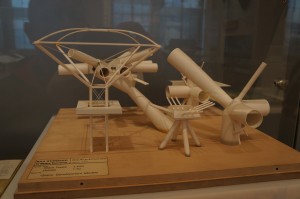

Also on display was this model 3D powder printed model of the entire Sagrada Familia (above). Producing a model of such complexity as a plaster cast would be achievable but in this case the powder printed method was chosen. Most likely due to the sophistication of each ‘spire’ component and it’s relationship to the next. Certainly for the conservation of time and as a retrospective piece this is very appropriate.  The above prototype testing model or stereo-funicular model is a replica of that used by Gaudi to develop his design for the construction of the crypt of the Colonia Guell. Simple materials like lead weights, string and a frame were crucial aids to design in Gaudis workshops and demonstrate the value of simple methods of creation or problem solving through making.

The above prototype testing model or stereo-funicular model is a replica of that used by Gaudi to develop his design for the construction of the crypt of the Colonia Guell. Simple materials like lead weights, string and a frame were crucial aids to design in Gaudis workshops and demonstrate the value of simple methods of creation or problem solving through making.

I’m glad I was able to catch this exhibition and would recommend anyone to drop by the Architekturzentrum Wien (Vienna) if they are in the city. Although it has now finished you can view the exhibition page here.

Scott