In any design workshop, managing waste is an ongoing challenge, especially when the waste produced isn’t in large enough quantities to interest commercial recyclers. In the B.15 workshop, one of our waste management responsibilities is to deal with Acrylic offcuts and waste produced through student modelmaking, most notably from laser cutting activity. Whilst the quantities may be small by industrial standards, the impact adds up over time and it has always been our intention to find a solution to this waste stream.

For several years the team have stored acrylic waste in the hope of finding a sustainable solution as opposed to the general waste route which many workshops often default to. A key complication is that Acrylic (PMMA) cannot be recycled with general plastic and requires a specialised process. Most local recycling services are not equipped to handle it and the services that do, often recycle the waste at sites abroad. After exhausting conversations with recycling companies coming up with no useful solution, we turned to a trusted local supplier, Floreeda Fabrications.

- Waste acrylic from B.15.15

- Granulated Acrylic Waste

- Another batch of waste acrylic off to be recycled

- Another batch of waste acrylic off to be recycled

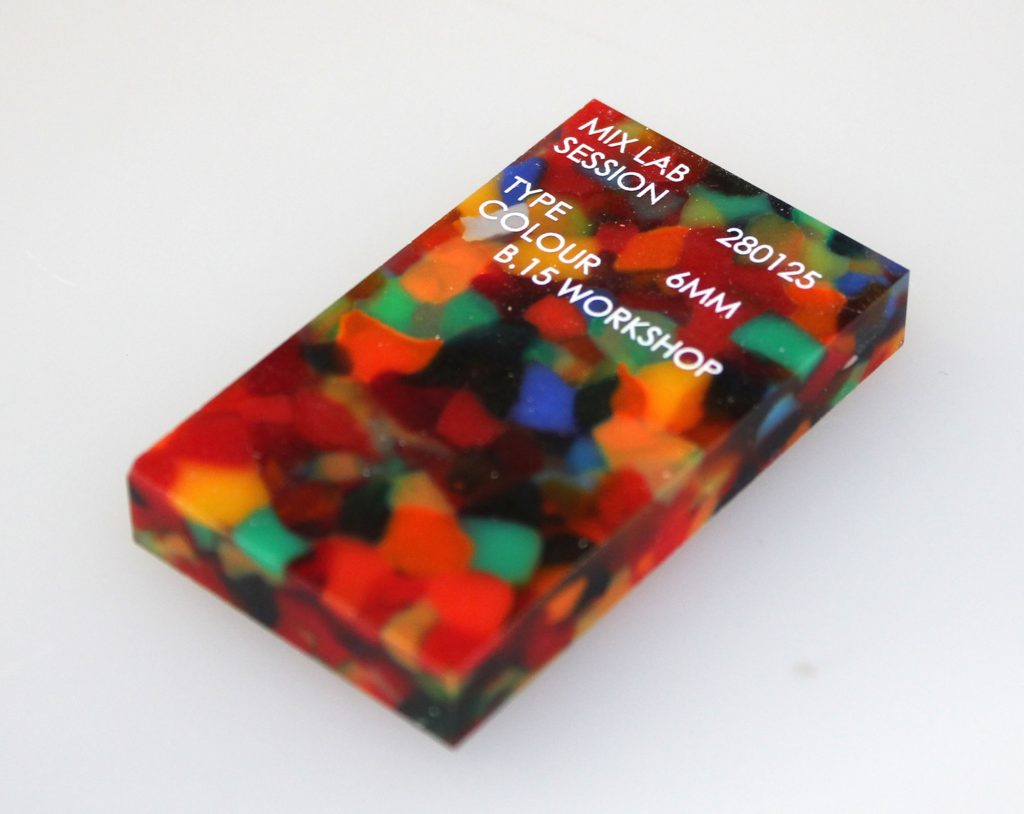

We found that Floreeda had been developing an initiative called REFLOW – a process that allows for in-house acrylic recycling. This takes end of life acrylic parts and recycles them through a clean manufacturing process with no additives, turning them into new, useable sheet material. This promotes a circular and closed loop economy within the industry.

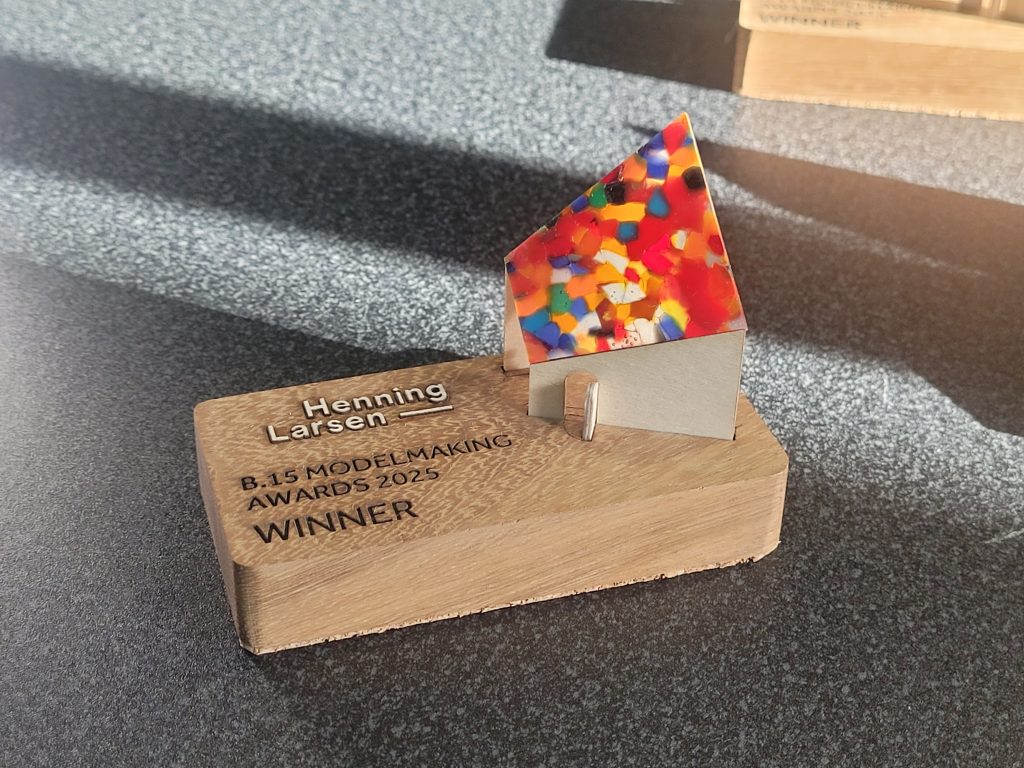

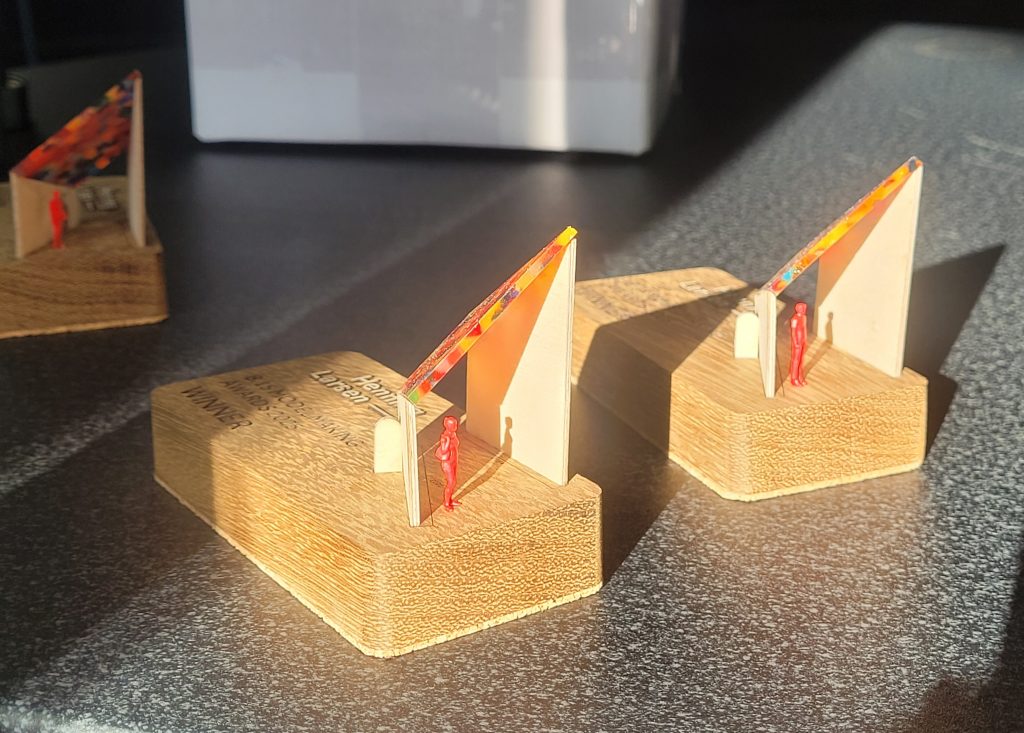

We’re now thrilled to say that we’ve received our first batch of recycled sheet material made entirely from the waste we had been storing over the years. Some of this recycled material has already been put to use, forming part of our B.15 Modelmaking award trophies that were handed out to this years student winners at the Manchester School of Architecture 2025 Degree Show.

Looking ahead, we’re excited to see how our students will incorporate the new REFLOW Acrylic into their work. Not only does the material perform like the original, but its origin gives it a story of sustainable thinking and responsible design. We also look forward to collaborating further with Floreeda to explore what other acrylic mixes and colours might be developed from our collected waste in the future.

This partnership represents more than just waste reduction; it’s a model for sustainable collaboration between education and local industry. This small but symbolic step shows how material circularity can be embedded into the culture of making. We hope it inspires others to consider how taking responsibility for even small-scale recycling can have a real impact, showing that patience and persistence to find solutions pays off.

Find out more about REFLOW here

– Lara Gerrard, Workshop Technician at B.15 Modelmaking Wrokshop