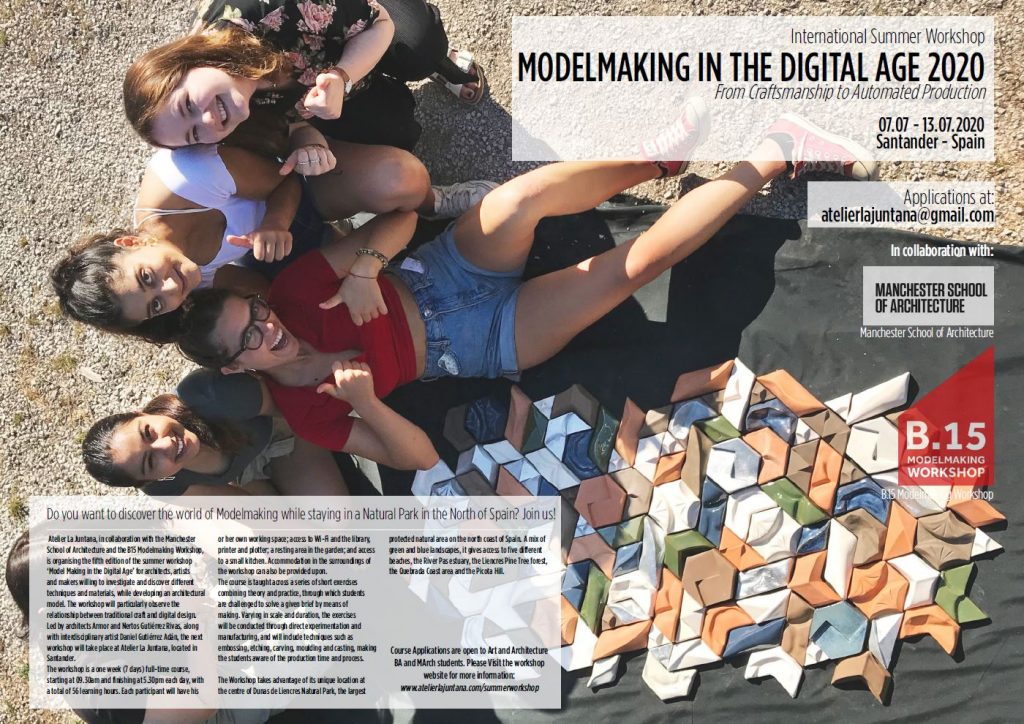

Not long after starting my role here I was asked if I would attend this years modelmaking summer school with a group of MSA students. I was very happy to accept and experience the course first hand having heard about it from previous students and my colleagues here at B.15. As part of the trip I noted our daily tasks for others to gain insight into the experience which are recounted here.

First process of day one- Ceramics

On our first morning in Liencres we were introduced to Armor, Nertos, Daniel, Yerba the dog and the rest of our class for the week. We were then taken on a tour of the workshop and site. Armor then gave a short lecture which showcased some of the workshop produce, explaining a little about the reasoning for the course and its future applications.

To begin, a short demonstration was given in which we were shown how to create a master tile with which the aim was to create a number of copies. We were given a number of different materials to work with, with the one exception being that the tile be made to the shape of a pre-cut template. The outcome of this would be a mosaic created from the whole group’s tiles, as we were all encouraged to choose a different shape. We began to work on our designs using Rollers, Clay thickness forms, Carving tools, Sponges and Clay smoothing tools.

Creating the plaster mould

Once we were happy with our master tile we were instructed to stick them down to an MDF base using a small amount of clay, ensuring the base of the tile was very flat to the MDF plate. A sectional wooden box was then placed around the tile, which we then sealed with clay ensuring it was water tight. Daniel then took each of our boxes outside where he submerged the tile with liquid plaster, leaving them to dry in the Spanish sunshine.

After a delicious international lunch (very nice) and a mug of Vermut we returned to our mouldings in which the plaster had now cured. We deconstructed the wooden boxes and removed the plaster block containing our master tile, carefully removing the form from the underside and eventually revealing the negative in the base of the block.

Using dry sponges we carefully cleaned the plaster negative, then chamfering the edges of the plaster block to reduce the chance of breakages.

- Bubusara Abekova designing her tile

- Clay master tile

- Ready for pouring

Making multiple tiles

Another short demonstration was then given, again by Master Daniel, on how to press clay into our plaster blocks to create copies of our original tile. This involved pressing clay of various colour (terracotta, black and white) into our negatives using hammers and short blunt posts, a little like truncheons. It was important to ensure that clay reaches every part of the mould, as this would guarantee a complete tile was removed.

The excess clay was then skimmed from the base of the mould using a wire and any imperfections in the base of the tile were then corrected. The tile was then coaxed from the mould with a mallet and laid onto an MDF board. We repeated this process as many times as we could within the time limit and laid all of our tiles on the wall outside to begin drying, turning them every 30-40 minutes to prevent bowing .

Time for the beach!

Day two in the workshop – Creating a tower

As with the previous morning, we were given a short lecture outlining the days’ tasks, today’s being to create a master tower from wood with the aim of casting multiple copies (similar to yesterday’s task in some aspects). The lecture contained images of previous towers, some ideas that may work well and others that may not. Armor then explained the limitations of each casting materiel and their possible uses in future application.

Going into the workshop we were each given a block of wood from which to work with. This was either a dowel of 50x1000mm or a rectangular block of 400x450x1000mm. We had access to a number of different pieces of equipment with which to create our wooden forms, some of these were: Bandsaw, Disk sander, Angle grinder, Lathe, Hand held woodworking tools and a Laser cutter.

Using these tools we set about creating our forms within the remit of the brief. An instruction was given to sand the pieces to a standard high enough that there would be as little texture imprinted on the inside of the silicone mould, also reducing the need for further sanding of the reproductions.

The final step before lunch was to coat the forms in a release agent, in this case we used Vaseline.

Pouring a silicone mould

The first task of the afternoon was fixing our towers to an MDF base using a screw. Similarly to yesterday, we placed a sectional wooden box around the tower and sealed at the base with clay. The towers were then submerged in silicone and the moulds agitated to remove any air that may have been trapped during the pouring process. It is important not to over agitate the mould as this will cause horrendous haemophilia like leaks, as I unfortunately found out. We then left our moulds to cure for approximately 24 hours.

Back to the tiles

Having sat in the sun for the best part of a day, the tiles were now dry enough to work into. We used a selection of different carving tools to remove excess material from the underside of our tiles, with the intention that they would dry evenly and quickly with a more consistent thickness.

Next came the task of finishing the tiles. Using a mixture of fine abrasive sponges, steel wool and sand paper, we began smoothing the surface of the tiles, aiming for a level of consistency. Returning them to the wall for a final drying, we now placed the tiles with their bases facing upward, again with the intention of even drying.

Time for the beach again!

- Creating the master tower

- Pouring the silicon

- Working into the tiles

Day three in the workshop – Etching and de-moulding

Now familiar with the daily learning routine, we started the morning with another presentation. This particular morning’s was a little longer than the previous, due to the amount of explanation needed. Today’s exercise was to prepare two zinc plates, with which the aim was to create two styles of etchings. One of these being a Photo-etch and the other being a Hard-ground etch.

To prepare both of our plates we first began by sanding the surface to a matte, but not scratched finish. It is important to ensure that the whole of the surface has been sanded, as this will enable the additive being applied to the face to adhere properly.

The grits of the sand paper we worked through were as follows: 400,800 and then 1200 grit, keeping the plate wet at all times.

Hard-ground etching plate

The plate being used for the hard ground etching was then cleaned, backed with alcohol based dye and left to dry. Once dry, each of us took our hard ground plates to a table where we were instructed to coat the opposite face in a solution made from a concoction chemicals, notably turpentine, bees wax and gum rosin. (Highly flammable so take care)

Once this coating was applied, it was then set alight by Daniel using a blow torch. When the flames had subsided and the plates were cool enough to handle, we were encouraged to begin sketching some ideas that we could possibly use in our etching.

Photo-etching plate

We returned to our remaining sanded face of zinc, but this time applied a small amount of polishing compound which we worked into the surface using a cloth. Having suitably buffed, we then gave the plates a final rinse and dry.

The plates were now backed like the previous, however this time with brown tape and then we prepared to apply the photo sensitive emulsion to the reverse side. This application was performed in a dark room using a rubber paint roller, ensuring even coverage over the plate. The plates were then dried using a heat gun.

De-moulding of the towers

With the silicone surrounding our towers now finally cured and mine no longer leaking everywhere, we were instructed to begin the de-moulding process.

Beginning by removing the clay from the base of the segmented boxes, we then removed any pieces of excess silicone that may have leaked from the base (a lot of this in my case). This was followed by the removal of the box. A small screw was then inserted into the area of the tower that was protruding from the silicone, depending on the complexity of the form. This meant a pair of grips were able to be used to grip the screw and assist in removing the tower from the mould.

With the towers removed, we each cleaned the inside of our moulds ready for the first casting exercise using epoxy resin. There were choices between either solid colours of resin, or to add a small amount of alcohol based dye to create a sort of bleeding effect of colour through a clear cast.

The resin was mixed outside and each of us chose our preferred effect, the liquid epoxy was then poured and the same agitation process was applied to remove any lingering air pockets.

- Preparing the Plates

- Applying the dye

- Torching the hard ground etching plates

- De-moulding the towers

Day four in the workshop – Etching and casting continued

This particular morning’s lecture outlined a couple of things. First, we were informed of a task for later in the week in which we would be designing a screen for printing T-shirts. The process is ultimately the same as that of the photo-etching, with the difference being that instead of using a zinc plate a silk screen is used. These designs were to be created in teams of four or three.

Secondly, we were informed of how we were to develop and eventually acid etch our zinc plates. This was a fairly complicated process and involved using a number of potentially harmful chemicals, thus we all had to listen carefully to our instructions.

Photo-etching

To begin the mornings work, we took our now fully hardened photo etching plates and laid them over a piece of acetate. These pieces of acetate were printed with an individual section of the Nolli map of Barcelona, the goal of this being that each of us would have a different section of the map and that a collective print could be later made.

This zinc acetate sandwich was then placed into a machine which I can only describe as a mixture between a vacuum former and a sunbed. The purpose of this machine was to remove any air between the acetate and the zinc, whilst also applying a dose of UV light through the remaining clear areas on the film. This would mean that the areas exposed to the light would be photo developed and that everything starved of light would not.

Our plates were exposed to the light for 3 minutes, at which point we removed them from the sunbed vacuum machine and peeled away the acetate.

We now ran from the dark room with extreme haste into the workshop, where upon arrival we placed our plates into chemical baths for around a minute and a half. A soft brush was then used by each of us to remove photo emulsion that had not been exposed to the light. Our plates were then rinsed and left to dry in the sun.

Jesmonite casting

Our resin casts we poured the day previous were now dry enough to remove from our silicone moulds and so the task now came to de-mould them, all of the results coming out brilliantly.

This meant our moulds were now free to cast some Jesmonite with the option of adding additional pigments. The process for this was to mix the two components of the Jesmonite and whilst being conscious of time add the desired acrylic pigment. Mixing this pigment in such a way would mean a marbled effect would be achieved and as with all the previous, agitate.

Back to Photo-etching

As our photo etching plates were now suitably sun dried, it was time to place them into a bath of Nitric acid in order to etch away the areas of zinc that were now exposed.

The plates were left in the acid for a total of 30 minutes, brushing the surface every 3 or 4 minutes to prevent the build-up of zinc dust from slowing the reaction. If the reaction was slow to begin, as was mine, this was because of a very thin layer of photo emulsion still remaining in the exposed areas. To remove this, we were instructed to take a small amount of ammonia on a paper towel and scrub lightly, making sure to do this outside or with a respirator to avoid any inhalation of the fumes.

With the ammonia having done its trick, we were able to return the plates to the acid bath and once happy with the depth of the etch, we removed them from the bath and rinsed. Now the only thing remaining on the plate should be the cured areas of photo emulsion, which we then removed by plunging into a bath of caustic soda and water. The plates were now good to go and were rinsed and left to dry for a final time.

Back to the hard ground etching

With each of us having finished scratching our designs into our hard ground plates, it was now time to acid etch these as well. This process was very similar to that of the photo etching, with the difference being the time left in the acid. We set our timers for 7 minutes and submerged the plates in to the baths, lifting the plate from the acid and then returning it at 1 minute intervals, the purpose of this being to clean the plate of residue without making physical contact.

Once the time was up, we were each instructed to remove the plates from the acid and take them to Senor Daniel, who would inspect the plate and then inform you as to whether the plate would need uno, dos, tres or quatro minutes more in the bath.

With each of us having acid etched our hard ground plates, it was now time to remove the remaining black waxy coating which covered the surface. This was achieved by cleaning it with a petrol soaked cloth, cleaning this plate thoroughly was extremely important as any residual wax would mean the print could be affected. This again was left in the sun to dry, importantly not near a naked flame.

Final task of the day

Our final task of day four was to begin sanding our newly un-moulded resin casts. Using sandpaper of grits 400,800 and 1200, we began removing any imperfections on the surface of our towers.

- Newly un-moulded resin and Jesmonite casts by Alice Weng Sam Lu

- Polished Resin Cast by Enrica Agus Klümper

- Hard ground etching plates

- Acid etching the zinc plates

- Developed photo-etching plates

Day five in the workshop – Printing from our etchings

On day five we went straight into it with a demonstration on how to print from our newly etched plates. Before proceeding with the tasks Daniel had laid out four different examples of glazes on one of the tables in the workshop, we then placed our tiles next to the finish we liked best. He would later cover our bare tiles with our chosen galze ready for firing and we’d see the results the following day. We also selected one of our newly bisque fired tiles, with the intention of picking the flattest of our creations for an aluminium cast, also the following day.

Each of us began by ensuring our plates were dirt and dust free, then taking a small amount of printing ink which had been thinned with a fat based softener we began working the ink into our plates.

Daniel informed us that the cloth we were using to work the ink into our plates was a piece of loosely woven hessian, perfect for applying the ink and then removing the excess, which we then did until around 90% of the ink had been removed from the surface. We were also told that the amount of ink you leave on the plate during the removal process determines how dark or light your print will be.

With the plates now inked, the paper had to be prepared. This meant soaking the linen based parchment in a water bath for approximately 3 minutes prior to printing. With the paper soaked and the excess water removed, we were able to place our etching plate on the roller press (in the correct orientation), cover with paper and roll away! Our new prints were then peeled carefully from the etching plate and hung to dry. This process was repeated with our photo etching plates and then again as a group print for the map of Barcelona, however this was on a much larger scale requiring a larger roller press and great deal of thought to ensure all the plates were laid out in the correct orientation.

To end the day, we each removed our Jesmonite towers from our moulds and poured an additional cast with rapid setting concrete.

- Preparing the Ink

- Inking the printing plates

- Getting ready to roll

- Printing the Nolli map of Barcelona

- The finished Map

Day six in the workshop – Aluminium casting, tower polishing and screen print design

We began day by using our flat bottomed tile to commence making an aluminium version.

Firstly, we placed or tiles on a very flat surface and arranged them within a wooden box in such a way that left a gap of at least 20mm between. We then took a small amount of foundry sand and began sieving it over our tiles, taking care not to move them or the box. Once the tiles were covered in an even layer of fine sand, we were told to compress it around the forms until an even skin was achieved. Having done this, we were able to continue adding shovels of sand into the box, compacting extremely well with each layer. When the rim of the box was reached, we were given a straight edged piece of timber with which to scrape away the excess and ensure the surface was level.

This initial box was then very carefully placed to one side and a new empty box was again placed onto the flat surface. Within this box we were instructed to position two tapered wooden sticks called spurs, which were to be positioned 20mm from the first and last tile which we had arranged in the previous box. In other words, they were placed in such a way that the aluminium would reach every part of the tiles on its journey from the crucible, down the first spur hole and ultimately out the exit spur hole.

Once these dowels had been positioned, we were able to repeat the sand compacting process until this box was also full and levelled. The wooden spurs and the tiles from the previous box were now removed and any damage left in the mould was now repaired.

Now with extreme care, we positioned the first sand box on top of the second, ensuring the correct orientation.

It was then explained to us that you can use pretty much any metal to cast into these foundry sand moulds, providing its melting point is lower than that of the sand.

When the metal had eventually melted, and the raging inferno had subsided, Armor and Nertos began pouring the molten metal into our moulds. Having cooled for around 15 minutes, we were told the tiles could now be removed from the sand, importantly wearing a pair of gloves as the temperature of the aluminium was still over 500 degrees. We then picked up the tiles with a pair of grips and plunged into a bucket of cold water until cool enough to handle.

Our aluminium tiles were now ready to have their surfaces finished which was achieved by using a combination of grinders and wire wheels, this removed any imperfections from their surface and gave them a high level of sheen.

- Sieving sand over the tiles

- Preparing the mould for casting

- Letting the aluminium cool

Tower polishing

With the metal casting completed, the time had now come to finish polishing our resin towers to a translucent finish. To do this, we were instructed to wet the resin and then

proceed to sand the towers with increasing grits until an overall consistent finish was achieved, then finally buffing the resin to a gloss finish using a polishing mop and compound. It was essential that our towers remained wet throughout this process.

Further to this process we rinsed, dried and then applied a layer of oil to the tower’s surface.

The rest of the day was spent arranging our previous day’s work into an exhibition during which Armor and Nertos quizzed the group on their designs and production process.

- Polishing the towers

- An exhibition of the weeks work

- Resin Towers on the light box

We ended the day with a dinner in Liencres – Very nice.

Final day in the workshop Screen printing and awards

The final morning started with us starting to pack away the work we had set up for the exhibition and photographing the finished pieces. The completed pieces photographed particularly well in the sunshine!

- A set of towers from the master onward by Irina Corăga

- Ceramic Tiles worked well laid together in a pattern

- Hard Ground Engrave and Print by Thuróczy

- Used Plaster Tile Mouds

- Glazed tiles

At the same time, with each of the groups having finished their screen printing designs, we were talked through the process by Nertos. As explained earlier, the process was extremely similar to that of the photo etching. However, our designs which had now been printed on tracing paper were now laminated against a silk screen which had been coated in photo emulsion, as opposed to a zinc plate with the etching. The screens were now placed back into Daniels tanning machine and after 2 minutes they were ready for removal. We were now instructed to quickly take them to the bathroom, which now with the addition of a red lightbulb had become the bathroom-darkroom. In this newly purposed space we were handed a water jet, with which we were instructed to blast the screen and remove any of the photo emulsion which had not been cured by the sunbed-vacuum.

Our screens once dry were now ready for printing. This meant laying them onto a flat piece of textile (in my case a t-shirt), ensuring that it was in the correct position and forcing a layer of ink through the newly created gaps in the screen using a squeegee. We were now able to remove the screens and hang our designs up to dry, this marked the final process of the week.

- Aligning screens for printing

- Spreading printing in through the screen.ink

- Freshly printed items hanging to dry

After this, we were each presented with a certificate outlining our participation in the week’s course and thanking us for our involvement.

Lastly, before saying our goodbyes we had a group Polaroid photo with Yerba the dog.

Experience Summary

I felt that I was very welcome during the course; Armor, Nertos and Daniel were excellent hosts. They were very good at encouraging you to explore your design ideas, questioning you along the way. They also informed us when they felt your design may be a little ambitious, impractical or may not work, this was very useful to people who had little experience before joining the course. The course was well structured to an extent. For example, drying times of certain processes were considered and therefore laid out on staggered days to ensure no process was missed out. I also felt the choice of processes were very usable for the students when they return to the university. This is with the exception of the screen printing, however I still felt this was a thoroughly interesting and enjoyable exercise.

The location of the course was also a big plus point. All three of the tutors were clearly very experienced in what they were teaching as it was not very often that the students were left wondering what to do next after a demonstration. We were all often encouraged to join Armor and Nertos in activities after the day’s work had finished, which was very nice.

Students who took part were: Maryam Ajoor, Erin Edmondson, Bubusara Abekova, Alice Weng Sam Lu, Chada Elalami, Zakia Ahmed, Hani Namirra Nasir, Alice Vetrugno , Tara Aveyard, Enrica Agus Klümper, Irina Corăga and Mylan Thuróczy.

Course organisers:

Armor Gutierrez Rivas, Nertos Gutierrez Rivas, Daniel Gutierrez Adán

Saul Parker-Backhouse, August 2019

Apply here for more information about the 2020 MSA exclusive week:

atelierlajuntana@gmail.com

More information about the course can be found on the ALJ website here: http://www.atelierlajuntana.com/SummerWorkshop.html