Category Archives: Main News Feed

Mecanoo B.15 Modelmaking Awards

After many months of hard work from everyone at MSA the end of year show was officially opened at a private view event on Friday. We were pleased to include a new award recognising the use of modelmaking in students coursework.

Judging took place during Friday afternoon where we were joined by representatives from Mecanoo, Professor Tom Jefferies, Dr Ray Lucas to mark the short-listed work in person. From the outset it was clear this was going to be a difficult competition to win due to the high quality of the featured work.

Spending time to look at each piece in detail, the judges marked out of 50 based on our criteria.

The total scores caused a heated debate about the winners resulting in the decision to restructure our prizes from one to three winners for BA (Hons) as final scoring was so close.

Ernst ter Horst and Patrick Arends from Mecanoo noted that they were “inspired by the exceptional level of quality throughout and it’s important to stress these winners were all on a knife edge with scoring”

The winner of the MArch prize was of “outstanding quality and creativity delivering a fascinating model of beguiling interest!”

Winners were:

Overall BA (Hons) Winner – Paul Thornber

Highly Commended BA (Hons) 2nd Place – Sara Hammond

Highly Commended BA (Hons) 3rd Place – Thomas Smith

Winner of the MArch Prize -Â Hajir Alttahir

Individual descriptions of the winning projects written by the students can be found in the complete short list document available to view here.

We are thrilled with the response this award has had and are confident we can continue to recognise the great modelmaking work of our students with this as an annual award. As stated by Mecanoo we would like to repeat how close the scoring for this was and that every project picked was done so because of great quality and individual attitude to making which was believed to be fantastic so well done to everyone this year!

Good luck in your future careers!

Scott and Jim at B.15

Mecanoo B.15 Modelmaking Awards 2015 Shortlist

The last month has been somewhat chaotic here in B.15 as the deadlines and come and gone we are still working towards one final date. This Friday our annual end of year student show will be accompanied by an all new award for modelmaking as we previously announced.

The short-listing for this award has now been completed and can be viewed along with descriptions of the projects by clicking here.

The award will be judged in person by ourselves, Mecanoo, Dr Ray Lucas and Head of MSA Tom Jefferies this Friday ahead of the opening and presentations at 17.30.

Good luck to all nominees!

Scott and Jim

B.15:45 Extended Interview with Sally Stone

In continuation of our individual extended interviews on modelmaking for B.15:45 here is Principal Lecturer Sally Stone talking about the uses of models in her Atelier, Continuity in Architecture.

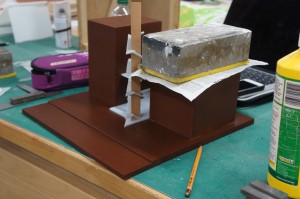

‘Wood Street Mission’ 1:20 Section Model by Katie Williams

Year 6 MArch student Katie Williams wrote about her final major modelmaking project for us:

This project is successful as it carefully balances necessary detail with material choices. The scale of 1:20 is perfect given the amount of layered detail Katie chose to show in her construction and the choice of this corner section was well considered as it shows a good selection of details and finishes that would expand throughout her whole design but are not necessarily required in their entirety to understand their application.

The success of this project is largely down to planning and material awareness. Rather than making the medium her binding constraint and only working around a particular tool, Katie rightly chose to dissect her model into components to help her understand its form as well as considering the most appropriate method of manufacture to represent each part.

It is clear is how well Katie understands the assembly of her building and the lessons learned in making this presentation model no doubt only strengthen that.

Mecanoo B.15 Modelmaking Award

We are very pleased to announce in conjunction with our 45th year celebrations a new award for outstanding modelmaking at MSA.

The award will be sponsored by award winning architects Mecanoo who have recently expanded their offices to include a new Manchester branch.

“Model making is integral to the design process at our headquarters in Delft and we place a great deal of value in students who can demonstrate a love for the physical crafting and communication of space in architecture, landscape architecture, and urban design.

As such, Mecanoo is proud to sponsor an award which recognises high quality model making skills at Manchester School of Architecture – a school in a city which has become our UK home. We hope that this prize will encourage final year students to push that little bit harder to make their models as experimental, pragmatic (and beautiful) as possible!”

Francesco Veenstra (partner in charge of UK projects)

The Awards

Representatives from Mecanoo will be in attendance and along with UoM and MSA staff will judge the winners.

In addition to the award for your portfolio, sponsorship from Mecanoo and ourselves will provide a cash prize of £500 per winner.

Models will be judged on their overall quality, choice of scale, material choices, chosen methods and the models effectiveness at conveying your design features.

We hope this gives you more of an incentive to think about your modelmaking skills and strive to improve on the great results we have already seen this year!

Good luck!

Jim and Scott at B.15

1:100 ‘Parasite’ Context Model by Anca Trimbaciu

This case study by Anca Trimbaciu shows us her proposed building within its enclosed site context of two existing buildings. So as not to take the focus away from her design the massing of the context buildings was kept simple. Anca wrote down her thoughts on the project for us:

“As part of first year’s final project we had to go the extra mile in explaining our design and idea. Therefore, we had to create a presentation quality model. My entire year revolved around butterflies, that being the animal I chose, so my building was also connected to them, being an indoor butterfly garden, a space for recreation and relaxation.

My design is a parasite building in between other two existing ones, which covers a very small space and puts focus around the staircase and the idea of ascension. As you move up you gradually discover spaces that are more open and luminous until the last floor which allows a panoramic view of Oxford Road from the inside of a “green utopia”.

The model shows context, size and the purpose of my building. A section in the back of the model allows the viewer to see inside and observe how the building makes use of the adjacent existing buildings and how double volume appears during the ascension towards the top floor.

The model shows context, size and the purpose of my building. A section in the back of the model allows the viewer to see inside and observe how the building makes use of the adjacent existing buildings and how double volume appears during the ascension towards the top floor.

I used painted MDF for the adjacent buildings and the base of my model just to give an idea of their size and appearance, contrasting with my design through colour and texture. Other than that, the rest of my model is mostly made out of clear or grey acrylic as it was the best choice to either represent glass, metal or polished concrete. The triangular staircase is sustained by a wooden column which is covered in vegetation. Because the scale is only 1:100, I opted for showing ramps instead of creating each step out of acrylic.

During the making of this model I had my first attempt at using Autocad and laser cutting, and surprisingly, I succeeded. I learned how to spray paint in order to completely cover the texture of a material and I improved my skills in working with acrylic. I also got the chance to fully understand my building and its structure.

It has been two well spent weeks in the workshop and I am looking forward to my next project, even though starting a model might be scary at first, the results are most of the times really impressive and worth the time.”

The construction method for this model was well considered and, much like the building process of a 1:1 project, the order of assembly was orientated around the ‘core’ access, in this case stairs, providing support for the different levels.

Of particular merit here is the consideration to how the massing was created. Rather than being solid blocks, the context massing was made up by creating hollow boxes which were then coated with sanding sealer, sanded and painted. This method saves on material and overall weight of the model and can often be done for free with off-cut material.

Extended Workshop Opening Hours

Due to high demand on the facility we have been able to agree later opening hours for a trial period of 3 weeks starting May 11th and ending May 28th.

Due to high demand on the facility we have been able to agree later opening hours for a trial period of 3 weeks starting May 11th and ending May 28th.

The workshop will remain open Monday -Thursday until 19.30 when students will be asked to clean up your workspace as normal in preparation for the following day. These temporary opening times are as follows:

Monday 09.30 – 19.30

Tuesday 09.30 – 19.30

Wednesday 09.30 – 19.30

Thursday 09.30 – 19.30

Friday 09.30 – 16.30

This time is in addition to our normal working day (09.30 – 16.30) and therefore does not mean you should turn up any later than normal. If this period is found to be ineffective at reducing the stress on the facility it is unlikely we will be doing it again so please make the most of the time.

So far this year there have been some great models produced and we hope the next few weeks will see some more great results. Make the most of it!

Scott and Jim

‘Peacock Museum’ 1:50 Cross Section Model by Mahishini Vasudevn

In another First Year case study we asked Mahishini Vasudevn to tell us about her recently completed project for the ‘Resolution’ brief:

“For our first project, habitat, I chose Peacock as my animal client so I made a design that would stand proudly and attract the eyes of the people just like the Peacock would do. To portray this, my design had a cantilevered floor which protrudes over the pavement of my site in Charles Street. The facade was designed to have stained glass which had the same colours as the peacock. In my design I have mainly focused on grasping the attention of people instantaneously.

In order to convey the most information about my design, I made a sectional model to give an insight to the structural aspects and the interior detailing of the design like the cantilevered stairs and the circulation around the building.

In the case of materials, for the glass facade I have used coloured acrylic as it best represents the colour and transparency that is implied in my design. As for the columns, beams and floor joists I used Styrene H-columns which were sprayed in black to represent steel frames. The floors were made with MDF wood to replicate the wooden floors. The pathway with granite paving slabs was laser engraved on grey card to show the colour and the small amount of texture that I wanted to show. The interior was done with wood and acrylic. In my model I have tried my best to produce them in such a way that they almost represent the same materials that would be used in reality if it were to be built.

Through making this model I have learnt new techniques of model making. It has taught me more about my design like the structural connections and how a design comes together as I was able to have a 3D view of my design. I’ve learnt how to plan my work and handle time with care.

Model making has been the best experience I’ve had as a first year architecture student and I’ve enjoyed working in the workshop.”

This model is put together with a good selection of materials that help to demonstrate the different component of the design shown in section. Mahishini made good use of pre existing strip materials by choosing styrene H beams to construct what would be the steel frame of her building if made at 1:1. Strip materials such as these are extremely useful in section modelling and we hope to stock a range in the near future. In the mean time they are available from 4D Modelshop where you can also register for a student discount quoting either myself or Jim as your tutor here at Manchester.

This model is put together with a good selection of materials that help to demonstrate the different component of the design shown in section. Mahishini made good use of pre existing strip materials by choosing styrene H beams to construct what would be the steel frame of her building if made at 1:1. Strip materials such as these are extremely useful in section modelling and we hope to stock a range in the near future. In the mean time they are available from 4D Modelshop where you can also register for a student discount quoting either myself or Jim as your tutor here at Manchester.

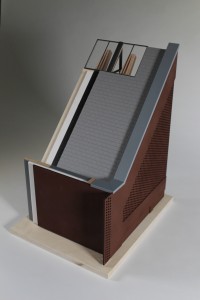

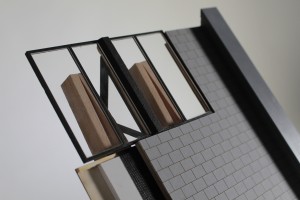

‘Arch Game Lab’ 1:50 Cross Section Model by Estelle Xin Yun Ang

First Year Student Estelle Xin Yun Ang has just completed a 1:50 section model of her proposal for the re-purpose of vacant space under a railway arch way. Estelle kindly described her project for us:

“I chose to build a model in which part of the facade was removed to communicate the details of interior spaces and the assembly of structural components. The railway arch was modelled as a section to show how it acts as the ceiling of my design. I modelled the underground and made a window to give a good view into the basement. The facade detail was quite important in order for me to express the sense of gaming, which was why I took the time to paint the tiny offcuts.

The exterior spaces surrounding my design is extensively graffitied which inspired me to design a gaming studio where the potential of play is explored. I incorporated game buttons into the design of the facade to convey my idea of gaming.

To model the context, I decided to use plywood as the texture provides a good representation of the brickwork for the archway. For the ground/base, I used mdf wood and applied wood stain to give a good contrast to the light coloured arch. I spray painted the laser cut mdf in grey to show the concrete floor plates. For the walls I chose to use vac-formed styrene to achieve a permanent curved shape. I added strips of acrylic between the two pieces of styrene to make up the thickness of the wall and that helped save some material.

I overcame the difficulties of modelling the curved shape of my design and I have learned to use different techniques on different materials to achieve the best result. After a few trials and errors I was able to understand the construction of my design. This is what I find interesting because there are so many ways in making a model and through experimentation I get to know which method works best for my design.”

What is clearly shown in this model is the attention to making each element correct for assembly. This patience and consideration is something we should all aspire to when designing and making. Often one of the hardest things to do during a project is accept that something you have made is incorrect and should therefore be re-made. Whilst this may seem like wasted time it is exactly the opposite and by taking a step back from the project to look at what you have learned you will see that such mistakes are necessary for your own understanding of the design as well as gaining a better understanding of material and machine constraints when making.

We hope to see more projects with this level of thought and consideration in the coming weeks leading up to the final submissions and in future first years.