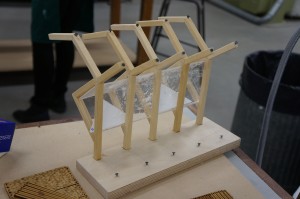

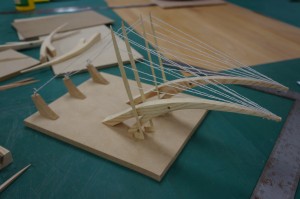

The last two weeks have been extremely busy in the workshop thanks to the 2nd year Creative Constructs briefs. By producing a series of models, each taking the idea to a more defined level of explanation, students are expected to demonstrate their understanding of aspects of structural design. These should include understanding of scale, junction detailing, overall strength of the structure and their ability to be repeated to work in conjunction with identical components.

Many of the projects we’ve seen for this brief have followed the trends of others in the group who have made a quick start. This has been an issue for latecomers due to the time restraints and capacity of the workshops both here and Chatham.

For students taking part in this project in future it’s worth noting the time involved in producing these projects. Many of you have been surprised at the amount of thought required to make your models a reality though really this shouldn’t come as a shock as that thought is essential to your learning. By taking the time early on to think about the different aspects of your idea and defining them accurately you can then take your information and apply those defined ideas to the creation of your model.

Without defined constraints you are simply guessing or making aspects of your project up on the spot which isn’t really helping you to learn anything. You should be able to explain the use of particular joints of construction methods based on research rather than their aesthetic or convenience to make as a model. There have been some interesting ideas appearing so far and I’m sure they’ll be more to come!

Scott

Last week 2nd year students were given the task of further refining their designs for structural elements. By taking their initial ideas to the next stage they came up against many more problems to solve in particular how joining replicated components would work in practice as they made seven identical units to work with one another towards supporting a structure or forming a building form.Â

Last week 2nd year students were given the task of further refining their designs for structural elements. By taking their initial ideas to the next stage they came up against many more problems to solve in particular how joining replicated components would work in practice as they made seven identical units to work with one another towards supporting a structure or forming a building form.

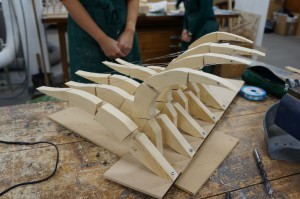

Marco Wan had an interesting approach to creating the curved planes for his design. This process is called ‘glulam’ and as the name hints at, involves laminating sheets together with layers of glue and material whilst clamped in a given shape. This produced a very strong formed shape that can and is used for many 1:1 building applications. Very nice to see a student employing this technique in their model development.

Marco Wan had an interesting approach to creating the curved planes for his design. This process is called ‘glulam’ and as the name hints at, involves laminating sheets together with layers of glue and material whilst clamped in a given shape. This produced a very strong formed shape that can and is used for many 1:1 building applications. Very nice to see a student employing this technique in their model development.