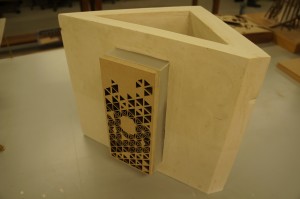

Made using an MDF mold this detail model aimed to demonstrate the window detail Becky was focussing on at her site. The mold proved to be the most time consuming aspect of the model but turned out successfully. It is always worth spending longer on mold design to ensure a good cast.

The mold was made using MDF which can absorb moisture from the plaster mix and therefore needs to be well sealed before pouring. Becky used Vaselene to act as barrier and release agent for the cast.

The internal void was made by using blue foam to allow for contracting of the cast as it cured and then be removed. This too was well coated in Vaselene to aid removal.

Once cured the MDF was unscrewed and removed before cutting out the internal blue foam. Additional window details were added using initially laser cut and then modified components.

Lauren and Becky decided to create their site master plan using 3D powder printed components on a laser cut plywood base. The completed model looks great and shows in detail all the shapes that make up the exiting structures their chosen site.

Lauren and Becky decided to create their site master plan using 3D powder printed components on a laser cut plywood base. The completed model looks great and shows in detail all the shapes that make up the exiting structures their chosen site.